Elastic putty for external wall

2021-04-22 922

Product parameters

| Test items | Technical index |

| State in container | No caking, even |

| Constructability | No obstacle in scraping and coating |

| Drying time (surface dry) / h | ≤5 |

| Initial drying crack resistance | No crack |

| Burnability | Hand burnable |

| Water absorption / g / 10min | ≤2 |

| Water resistance (96h) | No abnormality |

| Alkali resistance (48h) | No abnormality |

| Bond strength / MPa | Standard state ≥ 0.6 freeze-thaw cycles (5 times) ≥ 0.4 |

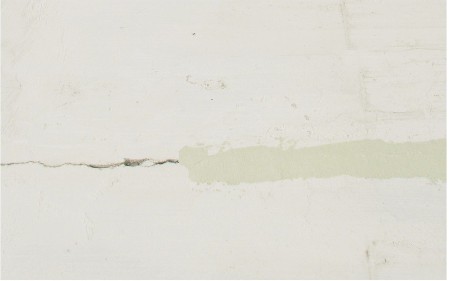

| Dynamic cracking resistance / mm | Base course crack ≥ 0.3 |

| Low temperature storage stability | There is no change after freezing at 5 ℃ for 4 h, and the scraping and coating are free of obstacles; |

(the data are for guidance only and should not be used as reference for preparation techniques)

Product characteristics

♦ It has strong adhesive force to wall and coating.

♦ It has good crack resistance, good elasticity, and can resist slight vibration of buildings and micro cracks caused by various reasons.

♦ It has good air permeability and keeps the base surface dry.

♦ It can be directly constructed on the wet base, and the subsequent process can be carried out directly after the slurry is dried.

♦ Natural texture, to ensure that the decorative effect of paint can be expressed.

♦ It has excellent aging resistance and good corrosion resistance.

Product application

1. Mixing ratio: 1kg slurry + 0.2kg powder + proper amount of water

2. Pour the additive into the container, then add the water into the additive and stir it properly, then pour the powder into it slowly, and fully stir it into a paste without powder particles and precipitation.

3. If the base surface is dry, the base surface shall be wetted until there is no open water before construction, and the base surface shall be stable, clean, flat and smooth, free of dust, oil stain, falling objects and other debris. Obvious pores and sand holes shall be blocked and smoothed with cement mortar, and sharp edges shall be removed.

4. Use a spatula to directly wipe the glue on the base surface. It is suggested that the scraping should be carried out in 2-3 times, and the thickness of each batch should not exceed 0.5mm, and the total thickness should be less than 2.0mm.

5. It is better to keep intermittent mixing.

The node treatment should be carried out according to the relevant specifications, and a layer of fiber mesh or non-woven fabric should be added.